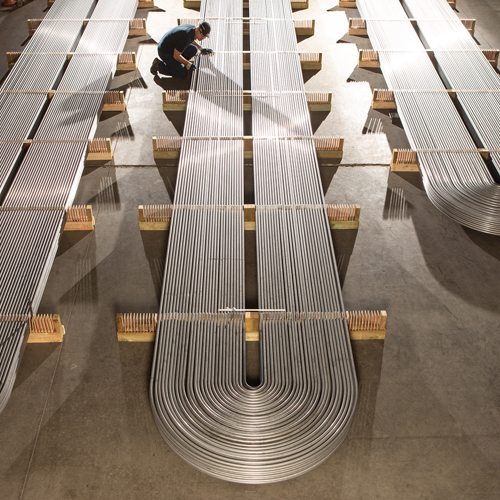

U-BENT TUBES

ST USA Inc an affiliation of Salem Tube heat exchanger tubes can also be supplied as ‘u’ bends or serpentines, manufactured according to various heat exchanger standards or to customer’s own specifications.

U-BENT TUBES

ST USA Inc heat exchanger tubes can also be supplied as ‘u’ bends or serpentines, manufactured according to various heat exchanger standard or to customer’s own specifications.

Standard Technical Range

- OD 0.374″ – 1.5″

- WT up to 0.25″

- Bending radii 0.049″ x OD up to 6′

- Bends can be supplied in accordance with TEMA R / ASTM SA/A556

- Leg length up to 49′

- Heat treatment where required by electric furnance or direct resistance

- Hydrotesting up to 10,000 psi

Additional Testing

- Dye penetrant of ‘U’ bend area

- PMI testing

- Heat Treatment

Heat Treatment

We are equipped to carry out heat treatment of bends plus a minimum 6″ of leg.

Heat Treatment Equipment

- Heat treatment equipment is computer controlled with the added facility of data recording.

- An argon protective atmosphere is used inside stainless and special alloy tubes during heat treatment.

- We can provide all types of annealing; solution annealing and stress relieving.

Measuring, Cutting, Deburring and Cleaning

- ‘U’ bends are produced, controlled and measured fully in accordance with relevant standards.

- All tubes are cut to the specified leg lenghts, ends deburred and the bores are internally cleaned with dried air.

Packing

- For roadfreight in timber fingers or skids.

- In strong open or closed wooden boxes depending destination.

- Each bundle is protected with plastic sheets.

- Customers can provide their own packing or Salem can prepare a packing plan.

- Detailed packings lists are attached to wooden cases to give quick and clear identification of contents.